Metal Building Guide: PEMB vs. Cold-Formed Steel

Building a new home or commercial space involves critical decisions early on—choices about materials, layouts, and timelines that set the tone for your entire project. If speed, efficiency, and durability are priorities, steel buildings are a proven solution.

At Armstrong Steel, we work with clients to design structures that meet their unique needs using two primary systems: pre-engineered metal buildings (PEMBs) and cold-formed steel (CFS) buildings. While both offer strength and performance, understanding their differences can help you choose the right fit for your project.

- Are PEMB and Cold-Formed Steel the Same?

While these two systems are often grouped together under “metal buildings,” they’re distinct in their materials and construction processes:

- Pre-Engineered Metal Buildings (PEMB): Built with heavy, hot-rolled “red iron” steel. Columns and rafters are factory-welded into rigid frames and shipped to the site, ready for quick bolted assembly.

- Cold-Formed Steel (CFS): Uses lighter, C- or Z-shaped steel members rolled from sheet metal at room temperature. Components are screwed together on-site, often without the need for cranes or heavy equipment.

Both systems have their place, but their strengths differ based on your project’s size, complexity, and long-term goals.

- Why Two Steel Building Options?

Steel construction surged in popularity during the 1960s as PEMBs replaced traditional hot-rolled beams. Factory-welded frames made it possible to span wide areas faster and more affordably than conventional methods.

CFS systems later evolved as a lightweight alternative, offering flexibility for smaller lots or urban areas where large equipment isn’t practical. Think of CFS as steel’s answer to wood stud framing—efficient, scalable, and ideal for projects where simplicity and speed are key.

- The Strengths of Cold-Formed Steel

Though it might seem like a newer innovation, cold-formed steel has a history dating back nearly a century. Its first documented use in U.S. construction was in 1925 at the Virginia Baptist Hospital, and it has since become a trusted choice for framing, roofing, and wall systems.

Advantages of Cold-Formed Steel Buildings:

- Corrosion and Pest Resistance: Galvanized coatings protect against moisture, while steel’s non-organic nature deters termites and other pests—no chemical treatments required.

- Durability: Lightweight yet strong, CFS components won’t warp, shrink, or twist over time.

- Lower Foundation Costs: With lighter overall weight, CFS structures often require smaller footings and less reinforcement, reducing concrete costs by up to 30%.

- Affordability: Steel is priced by weight, and CFS’s lighter materials mean lower costs without sacrificing strength.

- Fire Safety: Steel won’t ignite, with a melting point far above the flashpoint of wood—adding valuable time in case of fire.

- Energy Efficiency: Tight construction supports effective insulation, helping maintain consistent indoor temperatures.

- Design Flexibility: Works well for retail spaces, workshops, and modern residential designs with clean lines and open concepts.

Understanding the Limits of Cold-Formed Steel

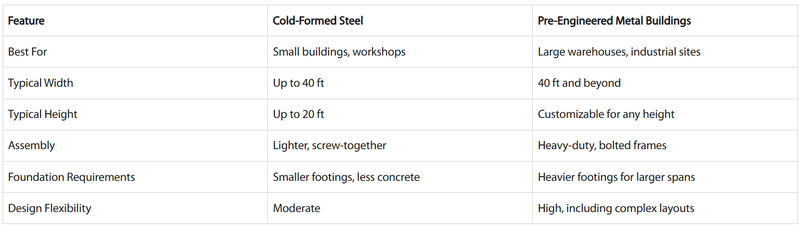

CFS buildings excel in smaller applications but are typically limited to:

- Widths of 40 feet or less

- Heights under 20 feet

- Simple roof designs, often gabled

For projects needing heavy-duty features like mezzanines or expansive clear spans, PEMBs are often the better choice.

Why Choose Pre-Engineered Metal Buildings?

PEMBs are fully custom-designed and fabricated in controlled factory environments. Each component is cut, welded, and drilled to exact specifications, then shipped ready for fast on-site assembly.

Originally developed in the 1930s for agricultural storage and hangars, PEMBs now serve a wide range of industries—from warehouses and manufacturing plants to recreational centers and retail spaces.

Key Features of PEMBs:

- Primary Framing: Heavy steel beams that form the building’s skeleton.

- Secondary Framing: Girts, purlins, and bracing for added support.

- Cladding: Durable panels to protect against the elements.

The Advantages of PEMBs:

- Quick Construction: Precision fabrication means no on-site welding or cutting—just bolt and assemble.

- Durability: Engineered to withstand extreme weather, including high winds, snow loads, and seismic activity.

- Design Flexibility: Clear-span framing allows for wide, column-free interiors ideal for warehouses, gyms, or aircraft hangars.

- Customization Options: Multiple roof styles, door sizes, window placements, and architectural details can be added to fit your vision.

- Sustainability: Less waste and efficient manufacturing support eco-conscious construction practices.

- Low Maintenance: Long-lasting materials and protective coatings reduce upkeep costs over decades.

PEMB or Cold-Formed Steel: Which Should You Choose?

Why Armstrong Steel?

At Armstrong Steel, we design and fabricate complete building systems tailored to your needs. Whether it’s a CFS system for a small workshop or a PEMB for a large commercial facility, our team delivers:

- Pre-welded clips and bolt-together parts for faster on-site assembly

- Precision-engineered components for structural integrity and longevity

- Industry-leading warranties for peace of mind

Your project deserves a building that’s as efficient and future-ready as your plans.

Ready to Build with Confidence?

Whether you need a lightweight, cost-effective solution or a robust structure for wide-open spaces, Armstrong Steel has the expertise to help you make the right choice.

Call us at 1-800-345-4610 or click ‘Price My Building’ to get a customized quote today.

Armstrong Steel—Built strong. Built smarter. Built for you.