How Pre-Engineered Steel Buildings Enhance Large-Scale Projects

When it comes to high-stakes builds—warehouses, logistics hubs, manufacturing plants, or commercial complexes—cutting corners isn’t an option. You need strength. Speed. Flexibility. And above all, you need a structure that works just as hard as the business inside it.

That’s why more companies are choosing prefabricated steel buildings from Armstrong Steel.

As a direct-buy steel building provider, we deliver pre-engineered systems that are precision-built for performance, scalability, and speed—without the headaches of conventional construction. Here’s why our buildings are the gold standard for large-scale projects across the U.S.

Built for High-Demand Environments

Large-scale operations don’t have time for delays or do-overs. Armstrong buildings are pre-engineered for the real world—factory floors with overhead cranes, high-traffic distribution hubs, aircraft hangars with 100′ clear spans. Our steel systems give you the structural backbone to support heavy equipment, complex workflows, and future expansion without structural compromise.

The difference starts with our in-house engineering. Every building is custom-calculated to meet your exact specs—down to snow loads, seismic conditions, and clearances. From layout to load paths, it’s all purpose-built.

Fast-Track Your Timeline

Traditional builds are slow. Multiple trades. Unpredictable delays. Material backorders. With Armstrong, your structure shows up pre-cut, pre-punched, and ready to assemble—with anchor bolt plans and labeled components that match your drawings.

This isn’t “off-the-shelf.” It’s engineered-to-order speed.

While stick-built projects crawl through months of framing and change orders, our clients are raising rigid frames in days—getting operational faster, generating revenue sooner, and skipping the constant budget surprises that plague conventional methods.

Maximize Your Space with Clear-Span Framing

Need to move forklifts, aircraft, or production lines through your space without navigating columns? Armstrong’s clear-span framing systems eliminate interior supports across massive widths—creating open interiors you can configure around your operations, not around structural limitations.

We’ve helped businesses build:

- Aircraft hangars with 200-foot clear openings

- Manufacturing plants with dual crane bays and mezzanines

- Fulfillment centers with tall pallet racking and high-speed conveyors

- Indoor arenas and training facilities with wide open playfields or riding rings

No pillars. No wasted square footage. No bottlenecks.

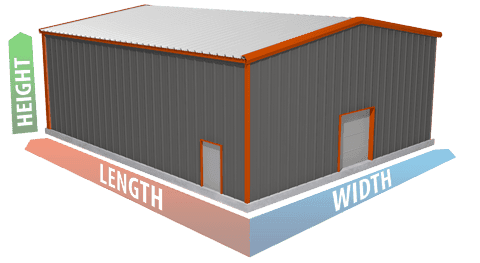

Future Expansion Built In

Growth shouldn’t require demolition. Armstrong buildings are modular by design, which means you can expand length, width, or height down the road—without touching the existing shell.

We use pre-engineered connections and panelized wall systems that make adding bays, loading docks, or new interior zones straightforward. And because your expansion is tied into our original design data, the new section fits seamlessly with the old—structurally and visually.

Designed for Difficult Terrain

Uneven ground or challenging soil conditions? No problem.

Steel is lighter than concrete and easier to adapt to tricky sites. Our engineers evaluate your location and provide recommendations that ensure long-term stability—whether you’re building in flood zones, hilly regions, or soft soil areas. That flexibility opens up locations traditional builders often avoid.

Heavy-Duty Durability. Light Maintenance

Armstrong buildings are made from high-gauge, U.S.-sourced steel with industry-leading coatings and finishes. You’re getting protection against:

- Corrosion and rust with optional Galvalume® panels

- Fire and flame spread with non-combustible materials

- Pests and mold that plague wood-framed structures

- Snow, wind, and seismic loads—all calculated for your zip code

And unlike traditional construction, your building doesn’t require constant repainting, shoring, or termite treatments. Minimal upkeep. Maximum uptime.

Integrated Energy Efficiency

Don’t let utility costs eat into your margins.

Armstrong buildings can be engineered with high-performance insulation systems, radiant barriers, and energy-saving roof coatings. Options like solar-ready paneling, ridge vents, and sunlit wall panels further reduce operating costs for large-scale operations.

Whether you’re running climate-controlled storage or trying to meet energy code benchmarks, our systems help you check all the boxes.

Tailored to Fit the Mission

Every component of your building should support what happens inside it. That’s why we never force clients into a “standard package.”

Armstrong Steel prefab systems are built-to-order. You decide the eave height, the number of bay doors, the insulation R-value, the framing system—even where the mezzanines go. We help configure it all.

From aircraft hangars to automotive shops to indoor arenas, our buildings are always designed around the real operational demands—not generic templates.

Why Armstrong Steel?

We’re not brokers. We’re not middlemen. We are your direct partner—engineering, fabricating, and delivering buildings that outperform across every metric.

- Precision manufacturing in our U.S. facility

- Pre-engineered drawings and foundation plans included

- Clear, bolt-together assembly for easy on-site erection

- Unmatched service from your first call to final bolt

When you need a facility that delivers value for decades, not just during year one, Armstrong Steel is the only call worth making.

Let’s Build Your Vision

Armstrong Steel has helped thousands of businesses scale up with confidence using our prefabricated metal building kits. From retail complexes and institutional facilities to logistics and manufacturing operations, we deliver high-performance structures on time, on spec, and on budget.

Call 1-800-345-4610 to speak with a dedicated building consultant

Or price your project online at ArmstrongSteel.com today

You bring the vision. We bring the structure to match.