How to Build a Data Warehouse That Survives the Next Decade

A well-designed data warehouse is the nerve center of any modern operation. It organizes massive volumes of information, enables real-time decision-making, and provides the physical infrastructure your IT systems need to run securely and efficiently. But just like you wouldn’t pour a foundation without an engineered blueprint, you shouldn’t build your data center without a future-proof structural plan.

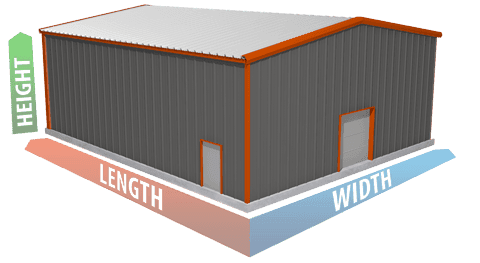

At Armstrong Steel, we help businesses like yours create durable, scalable, and energy-efficient facilities designed around operational performance. In this guide, we’ll walk through how to build a high-performance data warehouse using a pre-engineered Armstrong Steel building—and why our solutions are uniquely suited to power your digital infrastructure.

What Is a Data Warehouse?

A data warehouse is more than just a server room—it’s the centralized hub where your business’s digital intelligence lives. It brings together data from across departments: sales figures, CRM entries, supply chain metrics, customer insights, and more. With the right software, it transforms this raw information into clean, usable data for analytics, reporting, and forecasting.

But software alone doesn’t keep your warehouse online. Beneath every byte of stored data is a real, physical building. And not just any building will do. You need a space that’s structurally resilient, thermally stable, easy to maintain, and capable of adapting to tomorrow’s demands. That’s where steel makes all the difference.

The Rising Demand for Scalable Data Infrastructure

As cloud computing, AI, and remote operations expand, so do the demands placed on data infrastructure. Businesses across every industry—from e-commerce and logistics to healthcare and finance—are building new facilities to house servers, cooling systems, battery backups, and advanced networking gear.

Whether you’re hosting private cloud applications or managing sensitive operational systems, a purpose-built data center becomes essential. Traditional construction methods can be slow, rigid, and expensive. Pre-engineered steel buildings offer a better path forward: faster timelines, stronger performance, and a design that evolves with your needs.

Common Challenges in Data Center Construction

Developing a data warehouse is complex, and the stakes are high. A misstep in planning can lead to performance bottlenecks, wasted space, or skyrocketing utility costs. Here are some of the core challenges developers face:

- Construction Delays: IT deployment schedules are often tight. Delays in physical construction can ripple across software rollouts and operational timelines.

- Budget Constraints: Cost overruns are common in traditional construction. You need a structure that controls both initial and lifecycle costs.

- Limited Flexibility: Many buildings can’t adapt easily when your IT footprint expands or your rack configuration changes.

- High Energy Demands: Data centers consume vast amounts of power for cooling and uptime. A poorly insulated building will burn through your budget fast.

Each of these problems can undermine the long-term performance of your data warehouse—but steel offers a smart, strategic solution.

Why Armstrong Steel Buildings Are Ideal for Data Centers

At Armstrong Steel, we’ve engineered our metal buildings to solve the unique challenges of industrial-grade operations. When you choose to house your data warehouse in an Armstrong structure, you’re choosing performance, adaptability, and precision from day one.

Let’s break down what that means in practice.

Speed and Efficiency

Our buildings are pre-engineered, meaning every component is manufactured to spec before arriving on your job site. We ship precise kits with anchor bolt patterns, pre-punched panels, and bolt-together connections that minimize guesswork and speed up assembly.

Many of our clients complete erection in weeks—not months—especially when working with experienced steel crews. For your data warehouse, that means faster time-to-deployment and less risk of infrastructure delays slowing down business operations.

Long-Term Durability

Data centers need to run 24/7/365. That demands a structure that doesn’t just look good at install—but performs for decades.

Steel stands out as a high-strength, low-maintenance material. It resists moisture, pests, fire, and seismic activity better than traditional framing materials. At Armstrong, we enhance that durability with factory-applied coatings like galvalume for added corrosion resistance.

You’re not just protecting servers—you’re preserving uptime, safeguarding investments, and ensuring your operation runs uninterrupted.

Cost-Efficiency Over Time

While the initial cost of a steel building is competitive with traditional builds, the real value shows up over time:

- Reduced Maintenance: Steel doesn’t warp, rot, or attract termites, which means fewer costly repairs.

- Lower Energy Bills: Rigid-frame construction allows for thick, continuous insulation that helps regulate internal temperature—critical for server environments.

- Optimized Labor Costs: Our prefabricated kits reduce labor hours, meaning fewer surprises and tighter budget control.

These efficiencies free up resources so you can invest more in your tech stack and less in facility overhead.

Designed for Growth and Change

At Armstrong, we know your IT needs today won’t be your IT needs next year. That’s why we design buildings with growth in mind.

Our structures are inherently modular. Want to expand the footprint by 25% in three years? We can design that expansion into your original plan. Need to reconfigure interior layouts to accommodate new cooling units or equipment cabinets? No problem.

We also offer clear-span designs up to 300 feet wide with no interior columns. That gives you the flexibility to deploy hot/cold aisles, cable trays, and airflow corridors exactly where you need them—without being constrained by posts or trusses.

Optimized Environmental Control

Maintaining stable internal temperatures is one of the most critical aspects of data center performance. Steel buildings help make that easier—and more cost-effective.

- High R-Value Insulation Options: Reduce heat transfer and cut down on HVAC load.

- Reflective Roofing: Metal roofs with reflective coatings help deflect solar gain, reducing interior temperatures on hot days.

- Ventilation and HVAC Integration: Our clear-span frames accommodate rooftop units and ductwork without compromising structural integrity.

Together, these features help protect your equipment and support sustainability goals.

Built Around Your Operation

Every Armstrong Steel building is made to order—engineered for your use case, location, and layout requirements. That’s especially important for data infrastructure.

Whether you’re building a standalone server center or adding a data wing to an existing complex, we customize everything from door locations and access points to wall height, load capacity, and ventilation specs. We also accommodate specialty requirements like:

- Overhead crane support for lifting heavy hardware

- Reinforced concrete slabs for server cabinets

- Security vestibules and firewalls

- High-clearance entry bays for equipment delivery

This isn’t a one-size-fits-all metal shed. It’s a precision-built facility, designed with your digital operations in mind.

Maximize Space with Clear-Span Layouts

Floorplan efficiency matters. In a traditional wood or CMU structure, internal columns limit your ability to position server racks or airflow corridors. In contrast, Armstrong’s rigid steel frames enable wide clear spans—up to 300 feet with no interior posts.

This gives you:

- More usable square footage

- Better airflow management

- Easier maintenance and cable routing

- Greater freedom to adapt layouts over time

Think of it like an open warehouse floor—but engineered for high-tech precision and uptime.

Environmentally Smart Construction

We design buildings to meet today’s energy performance goals—and tomorrow’s too. For clients focused on sustainability, steel is an ideal choice:

- It’s fully recyclable and produces less waste than traditional builds.

- Our insulation packages reduce HVAC loads by up to 40%.

- Reflective roof systems minimize heat absorption.

- Optional solar integration allows you to future-proof your energy strategy.

Whether you’re pursuing a green certification or simply want lower operating costs, steel gives you more control over energy usage without compromising performance.

Turnkey Support from Design to Delivery

Armstrong Steel isn’t just a supplier. We’re your partner throughout the process.

From your first consultation, we assign a dedicated building consultant to guide you through every phase—from needs assessment and design to engineering and fabrication. We’ll help you determine the optimal layout, walk you through snow, wind, and load ratings, and make sure your structure is engineered for both local code and long-term growth.

Once design is approved, we fabricate your entire kit in-house and ship directly to your job site. Whether you choose to assemble it yourself or work with a local steel contractor, our detailed erection manuals ensure a smooth build.

Building Your Data Warehouse with Armstrong Steel

At Armstrong, our mission is to provide reliable steel building systems that help forward-looking businesses grow with confidence. That means engineering every component to meet performance demands, ensuring every kit is simple to assemble, and designing every layout to maximize value over the building’s entire lifecycle.

Whether you’re a tech firm expanding your cloud footprint or a manufacturer centralizing internal analytics, we’ll help you build a data center that’s not just strong—but smart.

Let’s Build the Backbone of Your Digital Operations

If you’re ready to create a scalable, secure, and efficient home for your data systems, an Armstrong Steel building is the right foundation. Contact our team today at 1-800-345-4610 or request a free quote online. We’ll work with you to design a steel building that’s engineered around your operations—and built for the future of your business.