Customer Profiles

Tire recycling facility built where an estimated 60 million tires have been dumped

Armstrong Steel Building Used As Tire Processing Facility

Colorado is home to the world’s largest tire dump with an estimated 60 million-plus scrap tires stockpiled mainly in three monofills. Each year, Colorado drivers alone add more than 4.5 million scrap tires to the piles.

That’s exactly what I. Roman, of Hudson CO, bought an Armstrong Steel building for. His environmental efforts: a tire recycling facility at the area's largest tire graveyard. He aims to turn thousands of tons of unusable rubber into products fit to re-enter the manufacturing process.

“The aim of our company is to recycle scrap tires for consumption in end-use markets, solving the problem of disposing of scrap tires while creating jobs.”

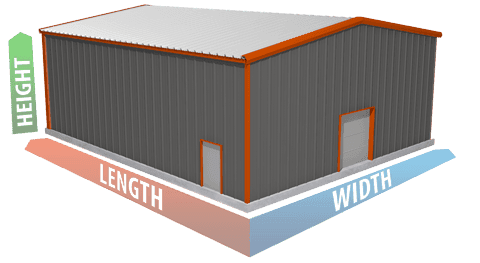

The facility features a large 131x196x26 Armstrong Steel building, which houses equipment for refining all types of tires, ranging from standard car tires, to airplane tires, to gargantuan mining tires. It uses extra large rollup doors on either side which require added bracing for the additional weight. Roman equipped the building with LED lights to conserve energy.

A sophisticated array of recycling equipment capable of harvesting thousands of tires a day

Tires that are brought into the site are eventually recycled into products that can be used in manufacturing, waste management, fuel, steel products, and more.

“Our Vision is to become a market leader in recycling scrap tires, serving the national TDF, salvaged steel, and ground rubber markets besides developing our own final products.”

Refined recycled rubber product, ready to ship

Originally from Mexico, Roman and his family moved to Colorado and some time later founded his tire recycling business. After a complicated history, Roman began pushing for common sense local laws and regulations on tire dump sites like this one. His background in engineering helped him to identify the necessary components he would need in order to realize this plan and shortly after, his enterprise grew to the point that he was ready for 24/7 operation.

That was when he called Armstrong Steel Buildings.

“I chose Armstrong Steel over other companies because it was the best option in the market. We didn't look into any others. We knew that it was the right choice for us to do.”

From start to finish, Roman says that his experience with the professionals at Armstrong Steel was very fast, easy and complete; he had no trouble erecting the building and all the pieces came appropriately packed and labeled. There was no guesswork.

The building has been the cornerstone of his activity at this location for several years now.

“I had a great experience with Armstrong. Their salespeople, their support people, the accounting people. All my issues were solved in no time. So congratulations on Armstrong Steel. You do a great job doing these kinds of buildings.”