Customer Profiles

“We were able to use the existing plans, add a few small changes, and we doubled the maintenance capacity of the building without significantly increasing the cost”

Tough & Attractive Armstrong Steel Building in the Gritty American Oil Fields

One of the most exciting places to live in the country, at the moment, has got to be North Dakota. Sure it lacks the pop culture appeal of Los Angeles; it isn’t the melting pot of consumerism and foreignism that is New York. It lacks the ethnic flavor of Miami and the techy swank of the Northwest, but it has something else that none of these places can boast – it has oil. Lots and lots of oil. And what’s happening in the state of North Dakota is nothing short of an economic explosion.

Back in 2001, North Dakota ranked near the national bottom in per capita gross domestic product. Since the discovery of the Parshall Oil Field in 2006 and despite the 2008-2012 global financial crisis; ignoring the lack of extensive infrastructure or a single metro area that was considered ‘on par’ with the financial centers of the east - North Dakota has catapulted to an astonishing per capita gross domestic product that is 30% above the national average. Add in a billion dollar state budget surplus, and you have the ingredients for developing a state of excitement, a state of growth, a state of change and advancement, a state of North Dakota.

Because the oil boom was almost a surprise to North Dakota, the pipelines necessary to transport the oil to the rest of the country could not be built fast enough to keep pace with production. The oil needed to be and still needs to be trucked.

Reaching the 217 oil rigs in the state to maintain machinery requires trucks. Getting supplies to the men and women working at these remote sites requires trucks. Trucks need maintenance, and Reliable Oilfield Resources needed a maintenance facility.

Cost was an issue, but so was safety

When Reliable Oilfield Resources (ROR) first approached Armstrong Steel about a pre-engineered steel building system, Jeremy Bjork was assigned as the project manager. “We were challenged because cost was an issue but safety was also a huge consideration,” he said.

Three months into the project Reliable Oilfield Resources notified Armstrong Steel that the steel building project would be delayed or scrapped because of zoning issues. “The property wasn’t zoned for this type of business so our client had to request that the county re-zone their lot or purchase new property. We did everything in our power to help them navigate the rezoning process and provided Reliable Oilfield Resources with all the information needed by their county to approve their request for re-zoning,” said Bennett Hietbrink.

Unfortunately, Reliable Oilfield Resources was unable to rezone the lot and the project was shelved, indefinitely.

Seasons passed, time elapsed, oil continued to flow from the ground in North Dakota and trucks continued to need maintenance. Reliable Oilfield Resources was committed to living up to its name and determined to find a location for its maintenance facility. “The economy was growing and people were moving in to the area, an equipment maintenance facility was needed,” offered Jeremy.

“When people think of the North Dakota Oil Boom their thoughts immediately go to things like housing and storage and equipment. But supporting structures, like churches, restaurants, stores, maintenance facilities, schools for the families of riggers – all of these things need to be built and need to be built quickly because communities are emerging very rapidly. The buildings also need to withstand the cold weather in North Dakota,” said Ethan Chumley, Armstrong Steel Building Systems CEO. “This is where a pre-engineered steel building is incomparable – they’re affordable, easy to erect, and can be finished to look like traditional construction, so the people using them don’t feel like they’re existing in a community of warehouses – their lives begin to look like the lives they left behind when they moved to the booming area.”

New land, same plans, a better steel building

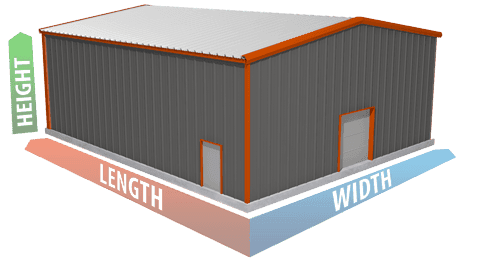

Several months passed and Reliable Oilfield Resources eventually found and secured new land which was zoned appropriately for their equipment maintenance facility. “We were able to use the existing plans, add a few small changes, and we doubled the maintenance capacity of the building without significantly increasing the cost,” adds Jeremy Bjork.

After the building was designed and the engineered drawings were approved and midway through the manufacturing process, the customer again approached Jeremy and said they wanted to add an addition to the building. “This would have stopped the manufacturing process and could have been costly,” said Bjork. “I had to help them find a solution which could provide the additional small office space, keep their costs low, and make it aesthetically pleasing.”

“When people purchase a pre-engineered steel building system from Armstrong Steel, they want it to look good and to perform,” says Eric Beavers, COO & VP of Armstrong Steel Building Systems. “We’re successful because we believe our steel building systems should look great and we refuse to put our name on an eye-sore.”

The Armstrong Steel Solution

Jeremy came up with a very inexpensive solution. Because the addition was so small, it could be built affordably with local contractors in a more traditional construction method and attached to the Armstrong structure. Armstrong Steel provided additional exterior panels as well as matching roof panels so no one would ever know that the addition was an afterthought. “We worked with their contractor, their budget and determined how much additional material the small add-on would require and we made that happen.”

Two years later, in North Dakota, oil is still a booming business. Trucks are still the backbone of the industry. The fleet that Reliable Oilfield Resources maintains has a comfortable new maintenance facility and what a pleasure it is for Armstrong Steel to have provided it to them.