Economical Steel Structures for Efficient Logistics Warehousing

Cost-efficient steel building structures have become the backbone of today’s most successful warehousing operations. Their unmatched durability, fast construction timelines, and ability to scale help logistics operators cut overhead, minimize delays, and stay competitive in an industry where time, space, and adaptability directly influence profit margins.

So why are steel buildings the clear choice for warehouses? Let’s break down how Armstrong Steel’s precision-engineered systems are transforming logistics facilities into smarter, stronger, and more future-ready spaces.

- Why Steel Works for Warehouse Construction

Steel warehouses are now the go-to solution for logistics because they rise quickly, adapt seamlessly, and deliver unmatched long-term value. This flexibility is vital in industries where storage demands shift rapidly and expansion plans can’t afford to wait.

Faster Build Times That Keep Operations Moving

Delays in logistics projects often trigger a chain reaction—backlogs in inventory, missed shipping targets, and dissatisfied clients. Pre-engineered steel buildings eliminate much of that risk. With Armstrong Steel’s precision-cut kits, major components are manufactured off-site and delivered ready to assemble.

Our experienced crews have completed warehouse installations in weeks—not months—helping operators hit tight timelines and start generating revenue faster. Compare that to brick-and-mortar builds, where weather delays and complex site work can drag on for months.

Design Flexibility for Evolving Logistics

Logistics isn’t static. As automation and AI-driven systems change how goods are moved and stored, warehouses must evolve too. Armstrong Steel’s clear-span designs create wide-open interiors free of obstructive columns—allowing easy integration of conveyors, robotics, and mezzanines.

We’ve seen clients double their usable floor space with multi-level storage systems while keeping their original frame intact. That kind of flexibility is rare in traditional construction but standard with steel.

Long-Term Value That Protects Your Bottom Line

Thanks to advanced coating and weather-resistant materials, our steel building systems are inherently resistant to corrosion, pests, and fire. Predictable maintenance costs and minimal repair needs make them a long-term asset—ideal for warehouse operators focused on maximizing ROI over decades of heavy use.

- Logistics-Friendly Features of Armstrong Steel Buildings

Every design choice affects efficiency and operating costs. Drawing on years of hands-on work with warehousing projects, our engineers recommend strategies that balance performance with cost control.

Energy Efficiency Built In

Natural light solutions like skylights and wall-mounted ventilators reduce energy consumption while improving indoor air quality—essentials for large-scale facilities. We often include these features in standard designs to help operators’ lower utility bills.

Space Optimization with Multi-Level Systems

Our steel frames can support integrated steel mezzanines and multi-story buildings with the correct design and engineering loads. For operators looking to increase usable square footage vertically rather than expanding the footprint, this is a game-changer.

Strong, Efficient Structures for Heavy Use

Tapered beams and columns distribute loads efficiently without adding unnecessary weight. This allows our buildings to handle high racking systems, forklifts, and continuous traffic while reducing material waste.

- How Steel Structures Enhance Day-to-Day Warehouse Operations

Climate Reliability for Sensitive Inventory

Steel’s compatibility with vapor barriers and insulation systems means you can maintain a consistent indoor climate—even in extreme weather. This is critical for businesses managing delicate goods like electronics or frozen products.

Uninterrupted Workflow with Clear-Span Interiors

Wide, open floor plans allow seamless movement of forklifts, conveyors, and automated systems. Clear-span widths up to 300 feet eliminate bottlenecks and maximize usable space.

Built for Demanding Environments

Warehouses see relentless use—constant loading, heavy racking systems, and vehicle traffic. Armstrong’s steel frames are engineered to thrive in these conditions with superior strength and longevity.

- More Reasons to Build with Steel for Logistics Warehousing

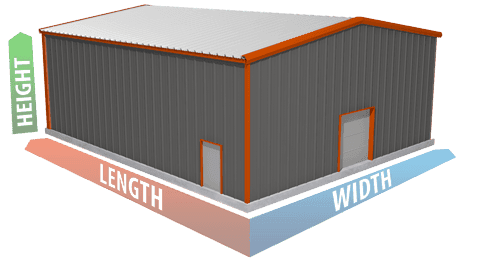

Designing a warehouse isn’t just about square footage; it’s about preparing for the future. Here’s why Armstrong Steel is the preferred partner for logistics facilities:

Ready for Advanced Technology

As automation, IoT monitoring, and AI systems become standard, our buildings provide structural support and adaptability that these technologies demand.

Expand Without Disruption

Our modular systems are engineered for growth. Add new bays, increase clearances, or even expand lengthwise—without tearing down walls or halting operations.

Resilience in Harsh Conditions

Protective coatings like Galvalume® prevent roof corrosion, while robust framing withstands heavy snow, high winds, and seismic activity.

Fire Safety Integration

Steel buildings resist fire better than traditional materials and are designed to accommodate fire suppression and security systems seamlessly.

Code Compliance Guaranteed

Every Armstrong building is engineered to meet local codes and safety standards, helping you avoid costly delays and compliance headaches.

Greener Operations, Lower Utility Costs

Energy-saving features like cool roof coatings and high-efficiency insulation create warehouses that cost less to operate and support sustainability initiatives.

- Build Smarter Warehouses with Armstrong Steel

At Armstrong Steel, we know a warehouse is more than just a building, it’s the backbone of your logistics network. That’s why we bring precision, innovation, and unmatched expertise to every project.

From initial design to delivery, our team will guide you in creating a facility that balances efficiency, adaptability, and long-term value.

Ready to future-proof your logistics operations?

Call 1-800-345-4610 to speak with a seasoned building consultant or click here to price your building. The right warehouse starts with the right partner. Let Armstrong Steel help you build it.