It’s true, pre-engineered steel buildings are generally half the cost of traditional construction methods, and can be erected in half the time. While there are multiple steps to any steel building project, if you want a project to be as efficient as possible, you’ll need to put some work in yourself. Keep in mind, you don’t want to sacrifice speed for quality. If you do decide to buy ‘cheap’ or agree to over ambitious delivery options, you may end up with a product that was manufactured quickly and arrives to the job site with holes that don’t line up or missing pieces.

So today, I decided to go to work for you. I figured the fastest way to get an answer was to go right to the source. I asked several of our steel building experts here to lend a helpful tip, and this is what they shared with me.

Have a plan

Organization is everything when it comes to a steel building project. Create a timeline and anticipate major milestones, like applying for your financing and planning for building erection before you receive your pre-engineered steel building. If you’re erecting your building with a group of friends or family, make a schedule to ensure their availability. Don’t scramble when your building arrives! Have a plan! Speak with a local civil engineer to develop a foundation plan. Be sure to apply for permits at the appropriate time because the permit process could be lengthy as well. You don’t need to wait until after you perform all of these steps to contact a steel building manufacturer. In fact, the sooner you contact a manufacturer, the better, because right now steel prices are low, but they are projected to rise in 2016. If you can plan it right, you’ll be ready for your steel building to arrive when you want it delivered. – Steve Barnes, Sr. Building Consultant.

Organization is everything when it comes to a steel building project. Create a timeline and anticipate major milestones, like applying for your financing and planning for building erection before you receive your pre-engineered steel building. If you’re erecting your building with a group of friends or family, make a schedule to ensure their availability. Don’t scramble when your building arrives! Have a plan! Speak with a local civil engineer to develop a foundation plan. Be sure to apply for permits at the appropriate time because the permit process could be lengthy as well. You don’t need to wait until after you perform all of these steps to contact a steel building manufacturer. In fact, the sooner you contact a manufacturer, the better, because right now steel prices are low, but they are projected to rise in 2016. If you can plan it right, you’ll be ready for your steel building to arrive when you want it delivered. – Steve Barnes, Sr. Building Consultant.

Embrace technology

Make yourself available. Sure, you can’t sit by your phone all day. We get it – you’re busy. But you’re designing a custom steel building, and we need your input! You get to pick out your doors and windows, and you get to decide what color your building will be. We need you to make the choice, because we won’t make those choices for you, and you wouldn’t want a company to make those choices for you anyway! When you receive any papers from your building manufacturer, ask for them electronically and send them back electronically. If you have questions, at any time, shoot your project manager an email. Be ready to work through email. If you’re erecting your building yourself, a tablet on the job site could be beneficial to keep track of inventory and help you communicate with your crew. Pencil and paper is an old school, tried and true method, but if you can save files ‘on the cloud’ you’ll be much more efficient. – Drew Snyder, Director of Technology.

Review and sign drawings promptly

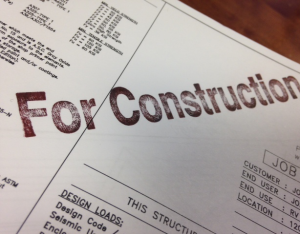

Throughout your steel building project, you’ll most likely approve sets of drawings before you can move on to the next step. We can work as fast as you can, so get those drawings back quickly and schedule your building for fabrication! The first set of drawings are the approval drawings. These drawings are emailed to you and require your direct attention. This is where you’ll mark up your building, add or remove openings, change dimensions etc. You get it. Don’t let these drawings sit in your inbox or on your desk! Your building project won’t advance to the next step unless you review the drawings and send them back to us. After you sign off, engineers will begin to work on your permit drawings. This might take some time so sit tight! Afterward, you’ll receive the construction drawings used to erect the building! Remember, while it isn’t smart to rush this process, if you can get everything back to a project manager in a timely fashion, your chances of getting a favorable delivery date increases. – Shon Cochran, Project Manager.

Throughout your steel building project, you’ll most likely approve sets of drawings before you can move on to the next step. We can work as fast as you can, so get those drawings back quickly and schedule your building for fabrication! The first set of drawings are the approval drawings. These drawings are emailed to you and require your direct attention. This is where you’ll mark up your building, add or remove openings, change dimensions etc. You get it. Don’t let these drawings sit in your inbox or on your desk! Your building project won’t advance to the next step unless you review the drawings and send them back to us. After you sign off, engineers will begin to work on your permit drawings. This might take some time so sit tight! Afterward, you’ll receive the construction drawings used to erect the building! Remember, while it isn’t smart to rush this process, if you can get everything back to a project manager in a timely fashion, your chances of getting a favorable delivery date increases. – Shon Cochran, Project Manager.

Be ready for steel building delivery

Has your foundation been poured and allowed to time to cure? Is your building site accessible for the delivery truck? Is your land ready? Is your crew on site? Do you have a forklift to unload your building? You’ll need to answer ‘Yes’ to all these questions before you can properly take delivery of your steel building. When the day comes to take delivery of your building, there are only a few steps left. The building components will arrive banded in bundles. The driver will give you a load list that you will use to account for all the bundles that belong to you while you’re off-loading. You’ll give your cashiers’ check for the balance owed to the driver prior to unloading the building. After the driver is on his way, you will have a week to go through all the material, item by item, according to the inventory list that we emailed to you previously. Unload the building with the assistance of a forklift or different type of machinery that you arranged to have on your job site. – Trish Scully, Production Coordinator.

Learn from the Pros! Do you (or did you) have a special way to speed up a steel building project? Share it in the comments section below! We’re all about sharing secrets and stories to help the next person down the road.

Photo courtesy: HUHEZI

When you decide to

When you decide to  Next, you’ll receive those approval drawings for your review in your email. Now it’s time for you to create your masterpiece! We suggest using a red pen or a computer program to make modifications or any desired changes. Now is the time to

Next, you’ll receive those approval drawings for your review in your email. Now it’s time for you to create your masterpiece! We suggest using a red pen or a computer program to make modifications or any desired changes. Now is the time to  Now, builders aren’t stuck with only those two options. The third and most cost effective option is to get a building directly from a

Now, builders aren’t stuck with only those two options. The third and most cost effective option is to get a building directly from a  Finally, you’ll make arrangements for the delivery of your steel building. Make sure you’ve got your

Finally, you’ll make arrangements for the delivery of your steel building. Make sure you’ve got your  This is the key item to managing your own project. Up until recently, the only way to get a steel building was through a contractor or a steel building broker. But now, you have a third and more cost effective option, which is to

This is the key item to managing your own project. Up until recently, the only way to get a steel building was through a contractor or a steel building broker. But now, you have a third and more cost effective option, which is to